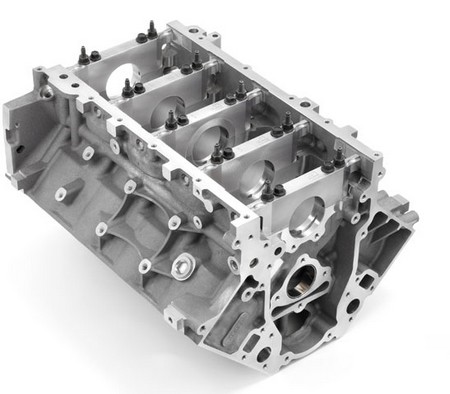

An engine block isn’t usually an issue of concern for most people. If yours get cracked, then you just call the auto repair shop up and they’ll fix it for you, right? Well, if you are a vintage car enthusiast or something similar, then you would know the trouble it will take you to get it repaired. However, chances are that if you’re such a motoring enthusiast, you would probably have thought of learning how to repair an engine block yourself.

The most effective method of how to repair an engine block is with metal stitching. According to automotive repair mechanics who are experts in engine repair, this is also known as metal locking, and involves the process of repairing a crack in an engine block without having to resort to welding. Metal stitching is a much simpler and cost-effective technique when compared to the more conventional welding.

The stitching pins that are used in the process of metal locking or stitching are made with zinc or copper plating, tapered plugs, threaded rods or dowels. Experienced lockers who are capable of stitching a cracked engine block together in minutes claim that anything that can be hammered into place is fair game. Lucky for the rest of us, metal stitching kits are actually available commercially.

True to its rough and ready approach, what metal stitching essentially entails is placing a stitch inside a crack with the aid of a drill bit, hammer or torque wrench. Some stitches come with shoulders which allow the stitch to be driven deeply into the crack. This ensures that the threads aren’t visible at the surface to guarantee an aesthetically-pleasing finish. Other types of stitches are accompanied with a pre-defined break-off groove that breaks off at a certain torque when a torque wrench is used. Some metal stitching kits provide a more secure fix by including a sealant or epoxy to be added after the initial stitching is carried out.

Now, why isn’t welding discussed here? Welding only works best when holes, not cracks are present in an engine block. Carrying out welding on a cracked engine block may actually precipitate more damage and engine block failure sooner rather than later. Welding is also more difficult to carry out compared to metal stitching because of the high temperatures and timing needed to weld cast iron. The time taken to carry out engine block repairs through welding also takes longer than metal stitching, which as stated earlier, can take only minutes to accomplish.