Anyone who knows a car has four wheels and a steering wheel will also know a turbocharger or supercharger will make it go faster; nothing gives a car a kick in the pants quite like these two modifications.

Superchargers and turbochargers have been around since the 30’s, but they weren’t as refined as the components installed into today’s machines. The way in which the supercharger works allowed for better performance than the initial turbochargers, which eventually faded out due to the invention of fuel injection. However, by the 80’s the turbo made a comeback, and has since been constantly refined to offer the amazing results we see today.

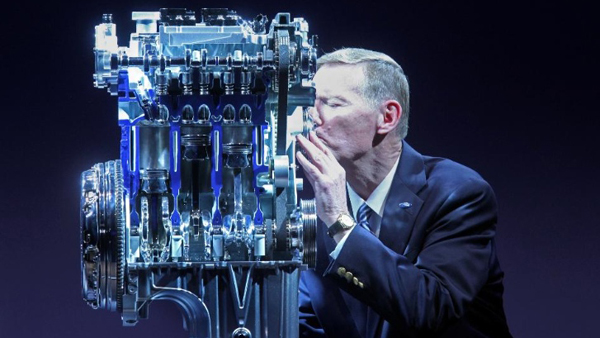

In this modern and environmentally aware society, car manufacturers are able to reduce engine displacement by installing a turbocharger or supercharger for extra power – cars with engines as small as 1.0L can now offer an added kick from turbos whilst maintaining good reliability (see pic above of Ford’s 1.0L eco boost unit). At the top end of the market, technology has offered performance cars two or more turbochargers (twin-turbo) or a supercharger for decades now, but advancements allow for greater reliability and the ability to counter “turbo lag”, something superchargers don’t suffer – this I’ll explain later on. Ultimately, smaller engine displacement means less fuel consumption and better CO2 emissions.

Both components work on the principle of forcing more air and fuel into the engine for a bigger explosion. Without going off topic and going into too much detail, I’ll describe the engine as essentially a big air pump working at atmospheric pressure, with the pistons creating negative pressure when they go down, sucking in air through the intake valve into the cylinder. The air is then combined with fuel and compressed when the piston moves up inside the cylinder. Once compressed it is ignited by the spark plug, and the subsequent explosion forces the piston back down again, where the gases leave the cylinder via the exhaust valve… and so the cycle continues.

So in the most basic form, a supercharger and turbocharger forces air into a standard engine running at atmospheric pressure.

How They Work

Turbocharger

You’ll find the turbocharger bolted to the exhaust manifold, where the exhaust dispelled from the cylinders spins a turbine. From this turbine, a shaft connects it to the compressor wheel, which is positioned between the air-filter and the intake manifold.

As the waste exhaust gases pass through the turbine blades, they start to spin, and the more exhaust passing these blades, the faster they spin. The spinning turbine blades turn the compressor wheel, and as the compressor wheel spins, it pumps air into the engine’s cylinders.

Turbos have to spin at speeds of up to 150,000 rpm, so most modern turbochargers use a fluid bearing instead of standard bearings. Using this type of bearing allows the shaft to be supported by a layer of oil, which cools the shaft and turbo components, plus it reduces friction.

The downside to turbochargers is they don’t provide an immediate response when you hit the accelerator. This is because it takes a moment (depending on the engine revs and how much exhaust is produced) for the turbine blades to get up to speed before it creates the right amount of pressure. This is called “turbo lag”, a feeling of slow acceleration followed by an almighty boost.

A way to eliminate turbo lag is to operate the car in the right gear at the correct speed, ensuring the turbo is operating in the right rev window – the higher the revs, the more exhaust passes through the turbine. Another way is to reduce the inertia of any spinning components by reducing their weight using ceramic blades. This allows the turbine and compressor to operate faster, producing boost earlier.

As previously mentioned, some engines use two turbochargers of different sizes to counter lag. A smaller one is used first because it gets up to speed faster, whilst a larger turbo kicks in at higher engine speeds to provide extra boost power.

Most turbochargers also use an intercooler to maintain the air supply to the engine is cool, helping performance – cool air is denser and contains more air molecules than hot air. The intercooler is like radiator, with air passing over it from the outside, as well as air passing through sealed passageways within.

The upside to turbochargers is the fact they are more tuneable as they come in different sizes, and boost (psi) can be controlled to suit different needs i.e. racing or street driving.

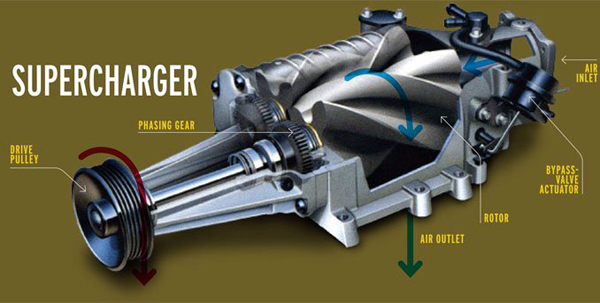

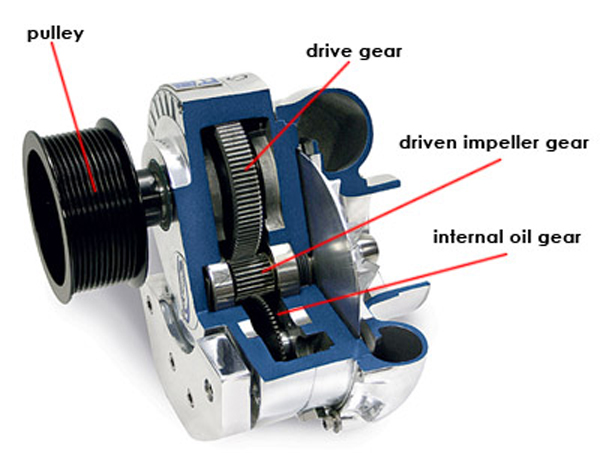

Supercharger

Superchargers work on the same principle as the turbocharger, although they create air pressure in a different way. Whilst turbochargers use waste exhaust to create air pressure, a supercharger uses the crankshaft. The crankshaft spins, and when the car is in gear and in motion, the gear drive, attached to a pulley via shaft and an accessory belt, operates the compressor pump.

Simply put: This car moves in gear, the gear drive spins the compressor, more air is forced into the engine. Some rotors in the compressor come in various designs, but its job is to ultimately suck in air, pressurise it and discharge it into the intake manifold.

Like the turbocharger, supercharger’s moving components create heat under exertion, so intercoolers are also needed.

As the supercharger works from the instant acceleration of the drive gear and doesn’t rely on the build up of pressure from exhaust gases, it doesn’t suffer “turbo lag”, one the supercharger’s upsides.

Another upside is a supercharger is far less complex than a turbocharger and requires less modification of the exhaust system; a supercharger is usually simply bolted to the top of the engine, thus making it less expensive to install and generally cheaper to maintain.

The downside of a supercharger is the fact it uses 20% of the engine’s power using its crankshaft to power the compressor. Although it manages to add an additional 46% back, it isn’t as versatile as the turbocharger at producing massive figures.

So if you are thinking about turbocharging or supercharging a vehicle, you may want to consider just buying a car that has them factory fitted, as it can be expensive and they have to fitted and tuned in perfect balance with your engine. Then you have the engine’s ECU (Engine Control Unit) and MAF sensor (Mass Air Flow) to consider; a slight unbalance could really affect your engine’s performance.