Manufacturing has been shifting towards automation for many years and it will not be long before everything is fully automated leaving little if any presence of humans in the plant. The reason why everything is moving in that direction is that robots increase efficiency, they are faster and can go days without stopping.

Nowhere has automation been embraced more than in the automobile manufacture. A huge part of making a car is now handled by other machines, some of the most common robotic applications in car manufacturing including the following.

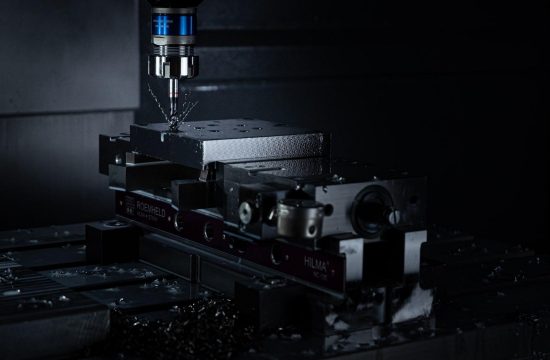

Assembly

Car manufacture involves a lot of heavy metallic parts that may be too much for a person to deal with. Before these parts are put into a car, they are made separately by robots just like RobotX with light arms that are quick and precise.

}Such parts that require sharp focus are the engine, the motor moving parts, and the pumps. Putting in small shoulder screws is also another vital job that only robots can efficiently carry out without missing anything.

Welding

According to Evans Manufacturing Co, Welding is an important process of car manufacturing, it is what puts most parts of the cars into place for use. Owing to how fast they move on the road, everything has to be properly welded into place and it needs pwht, otherwise, there would be disasters on the road. Welding is handled by large robots that have a higher payload which allows them to lift parts easily while welding at the same time. A car assembly plant without these types of robots cannot cut it. You can get a welding robot for sale easily these days if you plan to start an assembly plant, all you have to do is visit a good robot manufacturer and you will have lots of options to choose from.

Painting

Painting involves several stages of applying several layers of different kinds of paints and chemicals for the best results. The chemicals in play are very toxic and even with good masks, they can still cause problems for anyone who works in close proximity to them. Using painting robots is the best solution in this situation. Their consistency ensures that a very uniform coat of paint is applied in every part. Their precision is so high that they can never cross a line they are not programmed to breach.

Cutting

The shapes of the doors, the wheel rims, the chassis, and all other parts of the car are machine cut by robots. Every part of the car has to be symmetrical, anything that goes on the right side has to be reflected on the left side for the car to be balanced. This symmetry can only be achieved through the use of precision cutting by industrial robots, the programming behind this allows the robots to cut any shape out of any type of metal without straining or getting out of line. To be able to program robots like these, one must be able to understand the basics such as polymorphism in java.

Part Transfer and Machine Tending

The most dangerous part of car manufacturing is the movement of parts from one assembly point to the next. Things like pouring molten metal from melting crucibles into molding cauldrons can be a tad too risky for humans to be anywhere near, this is left to large robots. Moving of heavy parts like completed doors or the chassis is also work that is strictly assigned to robots. The only human input in these activities would be limited to maybe controlling some aspects of it from a safe distance.

Robotic Vision

This is a feature in robots that allows them to see what is missing by quickly analyzing parts of a car in the process of being made, it is called robotic vision. They use laser and camera technologies that scan all parts of the car and relay the feedback on what to do next. The things these robots can do include adjusting things that do not fit in well or simply detect something that needs to be replaced entirely. As time progresses by, a feature like this will improve drastically to take on more roles.

Collaborative Robots

As human involvement in manufacturing continues to diminish, there are still instances where humans and robots can collaborate to make the work more efficient. Robots in this category are called Collaborative Robots and they are designed with safety as a priority to make it easier for humans to work alongside them. Much of the work done by this collaboration is usually the light type of work like sorting out parts and cleaning.

Branding

The final part of car manufacturing is the addition of the insignia. Unlike other products, these logos cannot simply be printed on the body of the car, they have to be made molded out of metal, work that is also handled by specially designed robots that are able to carve out the even smallest details on any piece of metal. A car’s insignia is the most important part as it is tied to its identity. Therefore making them is a priority job that can only be done by robots.

Conclusion

It is estimated that robots will start taking over entire car assembly processes from 2024. Carmakers are pouring a big chunk of their profits into research and development of robots as they align everything towards achieving an autonomous kind of manufacturing in the future. How this job market disruption will play out is yet to be seen.