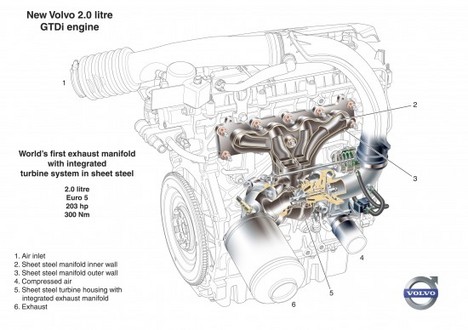

2010 Volvo S80, V70 and XC60 will be getting an all-new 2.0 liter four-cylinder engine which is developed with the latest technology to be powerful, smooth and most importantly, efficient. This unit has all the features of modern gasoline engines including turbocharger, direct injection and variable valve timing. It is fairly powerful for a 2.0 liter four-banger with 203 hp and 300 Nm of torque (320 overboost), and it also covers Euro5 standards with J-ULEV emission level.

|

Engine specifications |

|

|

Engine designation |

2.0 GTDi |

|

Engine type |

4-cylinder petrol turbo engine |

|

Cylinder displacement |

1999 cm3 |

|

Cylinder bore |

87.5 mm |

|

Stroke |

83.1 mm |

| Compression ratio | 10:1 |

| Valves per cylinder | 4 |

| Camshafts | DOHC |

| Max power output | 149 kW (203 hp) / 6000 rpm |

| Max torque | 300 Nm / 1750-4000 rpm, overboost 320 Nm |

| Turbo boost | 90 kPa |

| Emission level | Euro 5, J-ULEV |

|

Performance and fuel consumption (man/auto) |

Volvo S80 |

Volvo V70 |

Volvo XC60 |

|

Acceleration 0-100 km/h, sec |

7.9/8.5 |

8.3/8.9 |

9.6 (automatic) |

|

Fuel consumption, l/100 km |

7.9/8.3 |

8.1/8.4 |

8.6 (automatic) |

|

Emissions, grams, CO2 |

184/193 |

189/195 |

199 (automatic) |

The turbocharger system has been developed in cooperation between Volvo Cars, Borg-Warner Turbo System and steel component manufacturer Benteler Automotive. The turbocharger (K03) is the market’s smallest in relation to the engine’s maximum output. The turbo not only gives excellent performance properties, it also improves exhaust aftertreatment by enabling quick heating of the catalyst.

The turbine housing is integrated into the manifold, an efficient solution with which Volvo already had previous good experience. The difference is that the new manifold and turbine housing are made of sheet steel instead of a casting. The sheet is lighter and more compact and, above all, this system generates less heat owing to its extra insulating layer. This allows high gas flow temperature and thus more efficient combustion.

A manifold made of sheet steel is admittedly nothing new but so far it has only been used in combination with cast turbine housing. The new, fully integrated turbo package made entirely of sheet steel is a world innovation and has been patented by Volvo.

This innovative technology has made it possible to shape the exhaust ducts optimally to allow an optimal gas flow and generate the maximum pulse effect for the highest possible turbine efficiency. The pulse dynamics can thus be utilised to the limits in order to generate a high power output level across a wider range of engine revs. This translates into close to immediate response and good acceleration at both low and high speeds.

“High performance is important to many customers. However, being an innovative and highly efficient powertrain, there is also a significant gain in both fuel consumption and emissions with this technology” says Magnus Jonsson. “A Volvo S80 with this engine and automatic transmission consumes just 8.3 litres of fuel per 100 kilometres.”Efficient direct injection starts the turbo quickly

The new engine features direct injection. The injectors have seven holes for precisely controlled injection into each cylinder. The injectors are side-mounted.

Direct injection gives a high fill rate in the combustion chamber, efficient combustion and low emissions. Thanks to this high fill rate, the turbo also starts spinning earlier, delivering alert response from low revs. This in turn results in swift acceleration and good driveability even from low speeds.

Direct injection also contributes to quick and stable combustion at high loads, and thus smooth engine operation even when the accelerator is floored.

The injection system is supplied by Bosch.Twin VVT (Variable Valve Timing)

Volvo’s new GTDi engine utilises variable timing for both camshafts. Both the inlet and the exhaust valves’ opening times can be varied to optimise the overlap and ensure the correct fill rate in the combustion chamber irrespective of engine revs. This gives the combustion process maximum efficiency throughout the rev range and helps generate rapid acceleration at all speeds.

Both VVTs are of the conventional vane-type. The rotation of the inner and outer rotor is regulated by hydraulic pressure from the engine oil. By opening and closing the oil control valves, the oil pressure and flow through the VVTs are changed until the desired angular deviation between the inner and outer rotor is achieved. The oil control valves are controlled by software in the Engine Management System using feedback from the cam position sensors.

“By combining direct injection and VVT with our new patented turbo system, we can offer an engine with low fuel consumption and low emissions, without having to compromise on performance or driving properties,” says Magnus Jonsson. “We have created an engine that is as efficient in the city as it is on the highway. And since the design is based on an already-existing engine concept, we can offer more car buyers a highly fuel-efficient alternative at a reasonable price.”

In combination with Powershift or manual gearbox

The engine will be offered in combination with Volvo’s automatic six-speed Powershift transmission or a six-speed manual gearbox.

This new six-speed double-clutch automatic transmission combines the efficiency and driving dynamics of a manual transmission with the ease of a quality automatic transmission. The clutch activations are co-ordinated so that no torque interruption occurs during gear changing. This provides both the ease and permanent motion of a conventional automatic transmission and the performance of a manual transmission.