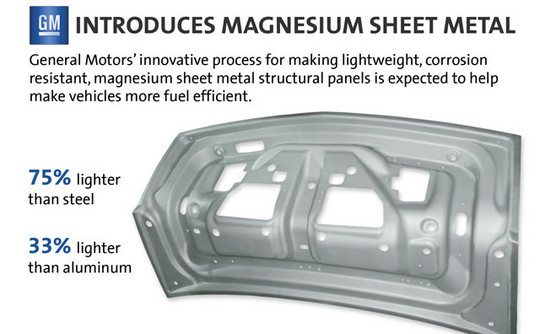

GM is pondering the possibility of using more lightweight magnesium sheet metal instead of steel and aluminum in their production cars to benefit from the significant light saving that it results in. Magnesium weighs 33 percent less than aluminum, 60 percent less than titanium, and 75 percent less than steel.

It is, however, not rigid enough to be used in cars. Not at least with current production methods. What GM wants to do is enable suppliers to provide significant amounts of magnesium sheet with a new making process that results in perfectly usable lightweight magnesium sheet metal.

They are currently testing an industry-first thermal-forming process and proprietary corrosion resistance treatment. GM’s patented process turns up the heat on magnesium to 450 degrees Celsius (842 degrees Fahrenheit), allowing the material to be molded into precise, rigid shapes. Given the advantages of using this material, it is well worth the hassle.

With this method GM hopes to extend use of magnesium from making parts such as from steering wheels to engine cradles, to structural applications. They’ve already made a production-ready magnesium rear deck lid inner panel that withstood 77,000 robotic slams and 250-kilogram impact drops without any issues.