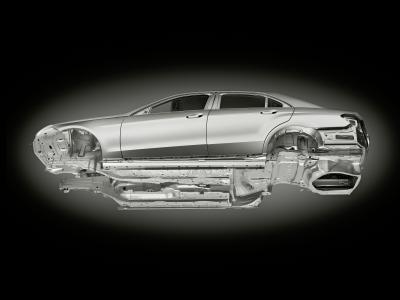

At 2009 EuroCarBody Award, the New generation Mercedes Benz E-class type W212 was voted as the car with the best bodyshell. A jury made up of about 400 conference delegates and board members awarded the Benz with this title due to its excellence at “Customer value” and “Innovative process, production and plant concepts”. Amongst the nine new series-production bodies presented, The E-class sedan challenged some big names like Jaguar XJ, Audi R8 spyder and BMW 5 Series GT.

“We are delighted to receive this award. EuroCarBody is after all the foremost conference for car body experts worldwide, meaning that it attracts top-ranking delegates,” explains Dr. Jörg Langner, who heads the Detachable Front End Body Parts team at Mercedes-Benz Cars Development. “Plus, it means we have come full circle: seven years ago, the previous E-Class model was crowned the winner of the first ever EuroCarBody Award, which has been presented annually ever since.”

The model series owes its triumph primarily to the top results it secured in the two voting categories “Customer value” and “Innovative process, production and plant concepts”. As for all other product characteristics, the bodyshell forms a foundation here on which the experts from the other specialist disciplines build. Dr. Langner analyses the result as follows: “It wasn’t a particular innovation which clinched it, but the harmonious overall concept.” In the “Customer value” category, for instance, the jury rewarded the exemplary safety concept and comfort level in the E-Class and its outstanding aerodynamics. For all these qualities the bodyshell is the most important element.

The active bonnet is just one of many features which illustrate how development of the E-Class body focused on customer value at all times. It reduces the risk of injury to pedestrians as well as offering E-Class owners a further crucial benefit: the active bonnet has a reversible design. So, if it is triggered by a minor parking bump, for example, Mercedes customers can simply return the bonnet to its original position – reactivating the system in the process – then continue with their journey.

“Our customer-focused approach is plain to see in the production concept for the Mercedes E-Class too,” points out Stefan Tritschler, Project Manager for Body Manufacture. “Guaranteeing supreme quality from the outset results in the ultimate in customer value.” This is made possible by sophisticated manufacturing and quality assurance methods. Besides the customary quality assurance measures, process monitoring procedures are employed for all joining operations to safeguard quality during each and every manufacturing step. The state-of-the-art RobScan robot-guided laser welding process, for example, is likewise subject to 100% monitoring. This new welding technology not only achieves a very high welding speed, it produces welding seams of the highest quality. During manufacture of the Mercedes-Benz E-Class body, RobScan welding is employed first and foremost for the doors, sidewalls and rear-end centre assembly.