Ford has come up with a new technique for making lightweight plastic parts which is apparently inspired by Aero chocolate bar!

You know how it has air bubbles in it, Ford realized if they inject gas into the plastic during moulding it results in a honeycomb structure that is 20 per cent lighter with no compromise on durability. This way less plastic is used, less energy and time to manufacture, reducing emissions and cost. Lighter parts obviously mean less fuel consumption and less emissions.

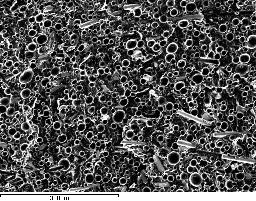

This new plastics resemble Aero chocolate bar on a microscopic level.

The new technology joins Ford’s other fuel saving techniques such as EcoBoost petrol engines, automatic stop-start engines, aerodynamic grille shutters and low rolling resistance tyres for maximum fuel efficiency possible.

Learn more about the chocolate-inspired technology:

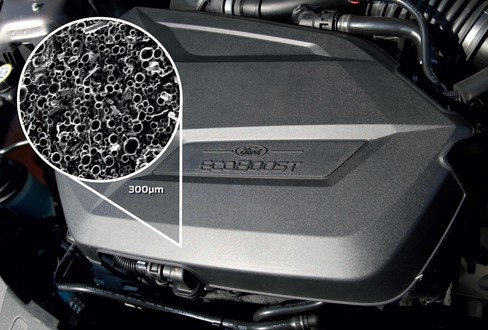

There are many areas where weight can be saved by changing the type or grade of metal used to a stronger, lighter material to trim kilos from the kerb weight. Plastic parts are an area where it is traditionally difficult to save weight without sacrificing strength, durability or function, but Ford has found a solution. MuCell technology introduces gas bubbles into the plastic as it is moulded, leaving a microscopic honeycomb structure. These tiny spaces save weight by reducing the amount of plastic used, without compromising the integrity of the part.

Weight plays a key role in vehicle emissions and reducing the overall mass of the vehicle results in improvements to fuel economy and carbon emissions. Vehicle weights have increased in the last 30 years to allow for much greater levels of equipment and radically improved safety attributes. Ford has targeted reducing weight while still providing class leading levels of equipment and 5-star Euro NCAP safety ratings.

MuCell brings a host of other benefits with lower pressures used to mould the plastic and up to 33 per cent more parts per hour than a conventional process. This increase in speed and efficiency reduces energy consumption, manufacturing emissions and cost for parts produced using the innovative technique.

Ford’s MuCell technology expert Carsten Starke is excited by the potential of the new process: “The first time I saw this plastic under the microscope I thought to myself it looks like an Aero chocolate bar!The bubbles in the chocolate change the taste, but in our plastics they save weight and making cars lighter reduces emissions and fuel consumption significantly,” he said.

“We are saving weight in many ways, not just by using this new plastic, because lighter cars handle better, accelerate faster and stop more quickly. For the customer it is win-win, the plastic is 20 per cent lighter without increasing cost or reducing strength and it will help make their Ford better in almost every aspect.”

The MuCell technology will see its first application in engine covers on vehicles such as Focus, C-MAX and Grand C-MAX, S-MAX, Mondeo and Galaxy in the next few years. Ford has committed to a minimum of 100kg weight reduction from even its smallest cars and 300kg from larger cars by 2020 as part of environmental initiatives. Weight saving, including deploying MuCell technology, is also achieved from other materials such as high-strength Boron steels which are used extensively in Ford models.