Just in time for the production of the new 911, Porsche launches a new high-tech paint shop at Zuffenhausen plant in Stuttgart.

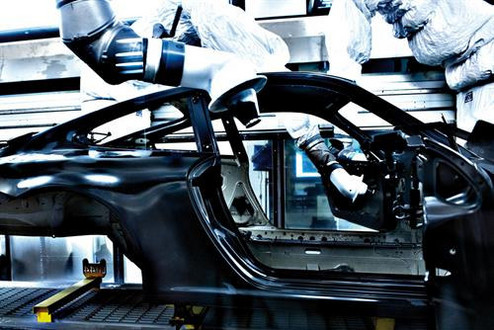

The dedicated facility uses cutting-edge technology to paint body shells inside and out in the desired colour and has the most advanced electrostatic paint droplet removal system and a wet-chemical exhaust air purification plant cut solvent.

The new facility is also quite economical and very green. The very efficient operation, with 70 per cent air recirculation, makes for especially economical energy consumption. In fact, Porsche has beaten the statutory limits by a significant margin thanks to the environmentally-friendly technology. The plant makes Porsche even more efficient, increases the premium car manufacturer’s flexibility and underpins the achievement of the high quality standards the company sets itself.

The 192 metre long and 52 metre wide paint shop building is where the body shells of the Porsche 911 and Boxster/Cayman model lines receive their anti-corrosion protection, and are painted and surface-sealed in a multi-stage process. This is performed precisely and synchronised with the sports car production process as a whole.

In building the plant, in which approximately 200 million euro was invested, Porsche called on internationally acknowledged specialists, also located in Baden- Württemberg, renowned for its automotive industry. These include the Stuttgart-based machinery and plant engineering group Dürr AG. As the prime contractor, it equipped the paint lines with ultra-modern application technology, dryers for hardening the paint as well as control and conveyor technology. Böblingen-based system supplier Eisenmann provided the pre-treatment system and the cathodic dip-coating plant, together with new conveyor technology and the electrostatic paint droplet removal system.