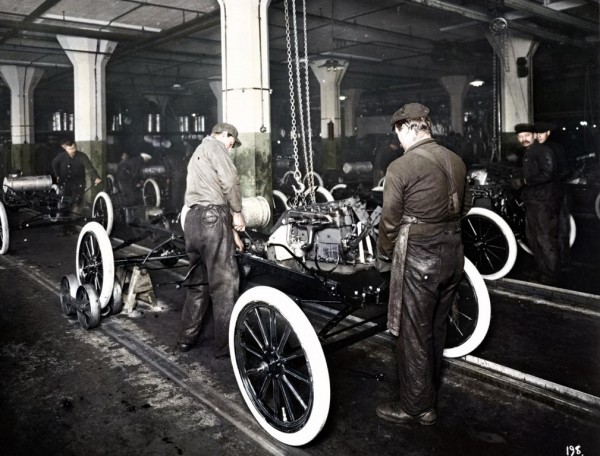

Ford is celebrating the 100th anniversary of the invention of the Moving Assembly Line by Henry Ford, and decided the best way to pay homage to the legendary industrialist is to revolutionize his concept. They are introducing a flexible manufacturing method to produce on average four different models at each plant.

The new production lines are to be in place by 2017 in order to meet surging customer demand. Producing various models at the same plant allows greater adaptability and faster production, which is the key to keeping up with the market. Ford also projects 90 percent of its plants around the world will be running on a three-shift or crew model by 2017, which will help increase production time more than 30 percent.

Another solution to boost production is the old trick of sharing platform. By 2017, all Ford vehicles will be built off nine core platforms – down form current 15 – boosting manufacturing efficiency, while giving customers the features, fuel efficiency and technology they want anywhere in the world. This will lower the cost of production, which in turn results in more affordable cars for end users.

Apart from the long-term plan, Ford also has the short-term ambition of producing 6 million vehicles in 2013. That is approximately 16 vehicles every 60 seconds! They are on track to achieve this.

“One hundred years ago, my great-grandfather had a vision to build safe and efficient transportation for everyone,” said Ford Executive Chairman Bill Ford. “I am proud he was able to bring the freedom of mobility to millions by making cars affordable to families and that his vision of serving people still drives everything we do today.”